Decreased Cycle Time with Renishaw Inspection Plus Update

The capabilities of today's FANUC control systems can provide powerful options to older machines that can improve your...

In This Issue:

Feature Article - FANUC Tool Retract (withdraw), Recover and Retrace

FANUC Tips & Tricks

Supporting Manufacturing Technology Education

FANUC Tool Retract (withdraw), Recover and Retrace

There are several forms of tool retract, each with specific uses. Many of these options are under utilized and companies that implement them can achieve substantial productivity gains. Tool Retract and Recover functions can retract tools for:

The following descriptions explain in brief, the operation of the Retract and Recover functions. Most of these functions are options and may also require hardware (such as push buttons) and PLC changes to work. Also, there may be limitations associated with each.

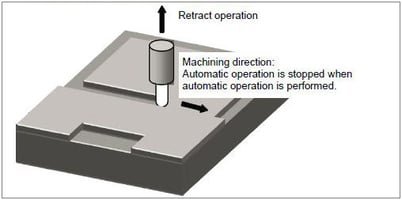

General Purpose Retract

In automatic operation mode or in manual operation mode, pressing the retract push button causes the tool to move (retract) in the axis in which a retract amount is specified by parameter #7730 (Usually the Z axis). The retract distance is set in parameter #7741 and the speed at which the axis retracts is set in parameter #7740. This option is available on 0i-B, 21i-B, 18i-B, 16i-B, 15i-B controls & newer and all 30 series controls.

This function is intended to retract the tool from the workpiece primarily when a tool breakage is detected.

Tool Retract & Recover

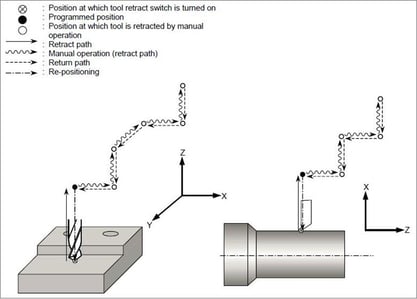

Using this very powerful option, a tool can easily be removed from a part & returned to restart machining. The tool retract and recover operation consists of the following steps:

Retract: Pressing the Tool Retract button causes one of the following to happen:

In either of the two cases above, additional manual moves can be added by selecting manual mode and jogging any axis. The control will record up to 10 end position moves of each axes jogged to be used to return the tool. FANUC calls this “WithDrawal”

Recovery (Return): Pressing the Recovery button after returning to automatic mode causes the tool to return to the initial retraction position following the reverse path of any of the up to 10 recorded end positions.

This option was available on 18B, 16B, 15B controls and newer, including all i-series and all 30 series controls. It was not available on any 0 or 21 series controls. Click here for more information.

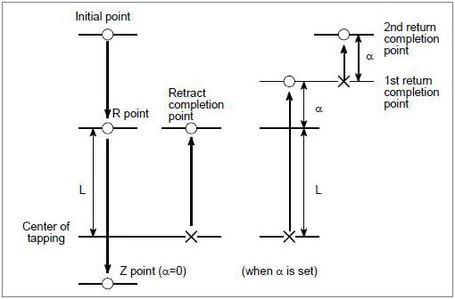

Retraction For Rigid Tapping

If emergency stop, reset or tool retract button is pressed while tapping in a Rigid Tap mode, the tap needs to be removed using the Rigid Tap mode or the tap may break or destroy the threads being cut into the work piece. To alleviate this problem, this option stores information about the Rigid Tap commands and uses this to safely remove the tap to the R point. If, under an Emergency stop condition, the tap does not retract completely out of the work piece, an additional amount α, is set in parameter #5382 thereby causing the retraction distance to increase.

This option is available for the 30 series M & T controls, but just M controls on the 0i, 21i, 18i and 16i series.

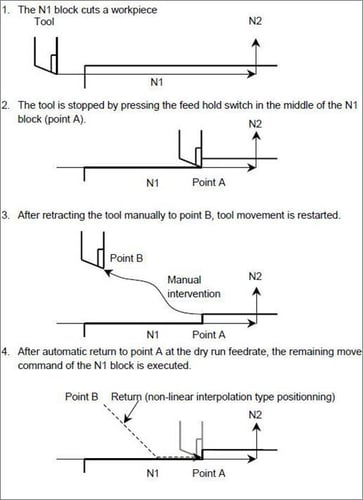

Manual Intervention and Return (0i Series)

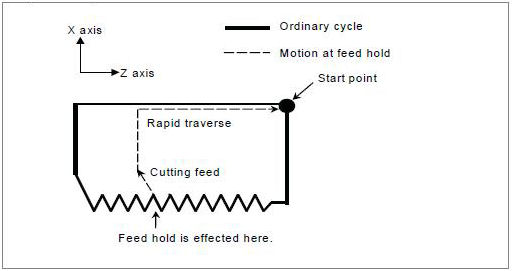

If Feed Hold is applied during automatic operation, Manual Mode can be selected and the tool can then be jogged off the part and to a spot where it can be checked (manual intervention). Upon returning to Automatic Mode and pressing Cycle Start, the tool will be returned to the position where it was before Feed Hold, or manual intervention, took place and the cycle will continue. This is described below.

One must be very aware of where the tool is when cycle start is activated because, unlike Tool Retract & Rover, the tool will return to the part using non-linear type positioning. This can result in a crash!!

Threading Retract (Canned Cycle) (T Series)

Normally, in a threading cycle (G92 or G76), if the Feed Hold button is pressed, the current threading pass in finished and the tool is retracted to the start point. Using this option, if the Feed Hold button is pressed, the tool immediately retracts using the same chamfer angle as programmed, then the tool returns to the start point.

Retrace

Retrace is used mostly for plasma and water jet machines but can also be used in turning & milling machines. This can be a complicated option but, in brief, turning on the retrace switch:

In either case the machine will continue in the reverse direction, processing block after block for up to about 100 blocks

During reverse execution, if the retrace switch is turned off, the reverse execution is stopped (after completion of the block if not in single block or feed hold) and forward execution is then restarted. Forward execution will continue until the spot where the retrace switch was turned on and the regular program will then continue.

Click here to read more about Retrace.

Manual Handle Retrace is similar to Retrace, except the MPG is used to move the axis in the reverse or forward execution mode (i.e. every click of the MPG in the minus direction will cause machine movement in reverse direction and MPG movement in the plus direction will cause machine movement in the positive direction).

Click here to read more about Manual Handle Retrace.

FANUC Tips & Tricks

To get rid of soft overtravel alarms 500-505 - Hold down the P and CANCEL buttons on the MDI panel while the control is powering up. This will ignore the soft overtravels until the first manual zero return is done.

Supporting Manufacturing Technology Education

CNC Engineering, Inc., FANUC FA America and Koma Precision, Inc. have joined forces to support the Manufacturing Technology program at Asnuntuck Community College, located in Enfield, Connecticut. This year, FANUC FA America donated three new FANUC control systems to students and staff of Asnuntuck Community College.

CNC Engineering, Inc. in Enfield, Connecticut and Koma Precision, Inc., based in East Windsor, Connecticut sponsored the 2nd Annual Manufacturing Technology Benefit Golf Tournament. The annual event, held in September, has raised $45,000 for the Manufacturing Technology program at Asnuntuck Community College. This year’s added donation from FANUC FA America is especially significant. According to Frank Gulluni, Director of Manufacturing Technology at Asnuntuck, “The control systems will assist in training students, in machine technology, electronics and electro mechanical technologies, benefiting hundreds of students in the next few years.”

ACC’s Manufacturing Technology program is instrumental in helping ready the manufacturing workforce through their educational courses. Numerous companies, throughout the State of Connecticut, have successfully hired graduating students from Asnuntuck Community College.

The capabilities of today's FANUC control systems can provide powerful options to older machines that can improve your...