Rotary Tables & Additional Axes

Our Rotary Table specialists will guide you through selecting the right CNC rotary table and integration solution for your FANUC CNC machine tool

Rotary Table Integration Experts

CNC Engineering, Inc. has integrated thousands of rotary tables to dozens of different machine tools. Our turnkey rotary table installation package features:

- In-field installation, completed in as little as one-day

- Our RT Cable Plus system: the best combination of durability, ease of use, and reliability on the market today

- Rotary Tables from leading brands like Tsudakoma, Kitagawa, Troyke, and Nikken

- Extended FANUC CNC services for ladder changes, options, upgrades, and spare parts

- Accessories like risers, faceplates, and tailstocks

- Thorough machine operator training

We are proud to work with the industry's leading Rotary Table brands:

RT Cable Plus Systems

The importance of a properly designed, and installed, Rotary Table cable system cannot be understated. Take a look at the difference between the two rotary table integrations below:

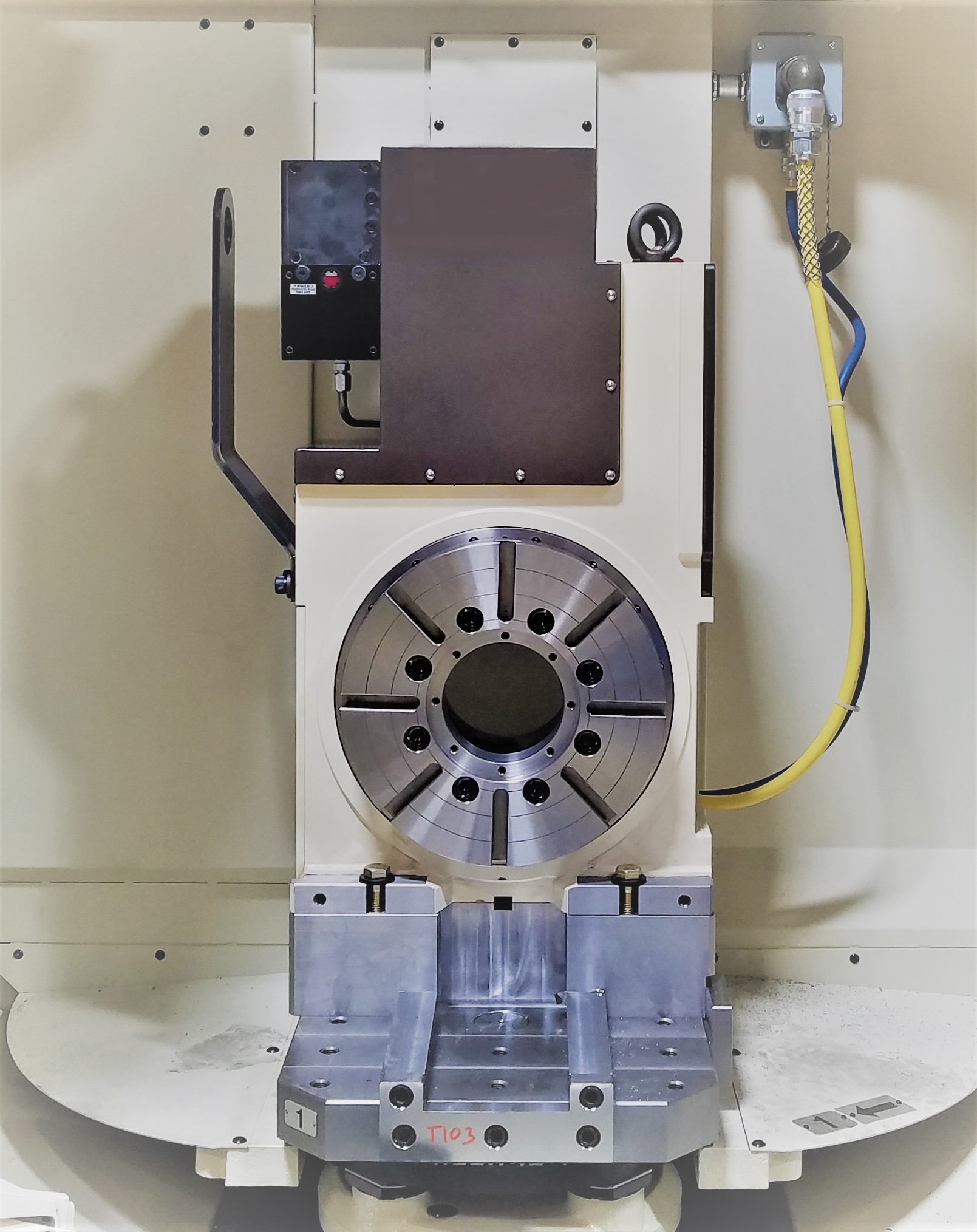

Our RT Cable Plus System

Our RT Cable Plus System

Our RT Cable Plus

Contamination

Zero Contamination: Our RT Cable Plus contains motor, I/O and shielded encoder conductors in a single PVC jacketed cable. The cable is highly flexible, durable, resistant to coolant contamination, and protected by strain relief on both ends (a steel-braided version is also available on request).

Connection

Our RT Cable Plus system is hard-wired to the rotary table which eliminates a potential contamination point. A single environmental quick disconnect connector is used to interface the table to the machine. This allows the table to be connected/disconnected with one quick turn.

Cable

One cable, rather than two, means fewer connection points, less wear, and lower contamination risk.

Location

The RT Cable Plus connectors are located away from chips and coolant and we add a spring management system to help minimize cable wear.

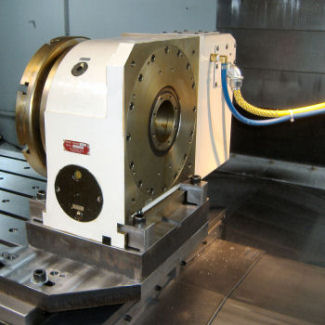

Their Cable System

Their Cable System

The Competitions Cable

Contamination

Risk of Contamination: Traditional sealtight cable is susceptible to cracking and splitting when exposed to some coolants and continuous flexing. Over time, cracking and splitting will lead to higher failure rates.

Connection

Their sealtight connections on the back of the rotary table create additional potential contamination points. These threaded connectors also make connecting and disconnecting the table a time-consuming and difficult process.

Cable

Two cables can create a tangled mess, which can cause premature wear. Two cables require four connections and four-times the chance for contamination.

Location

Locating the connection points close to coolant and chips creates a greater chance for failure, as traditional sealtight will collect coolant. Furthermore, the cables could easily be pinched during machine movement or part loading.

Ready to Expand Your Machine Capabilities?

Additional axes and Rotary Tables will extend the capabilities of your CNC machine tool so you can produce more complex parts.