Cell Control Retrofit from CNC Engineering, Inc.

Featured in Northeast Manufacturing News (www.mfgnewsweb.com)

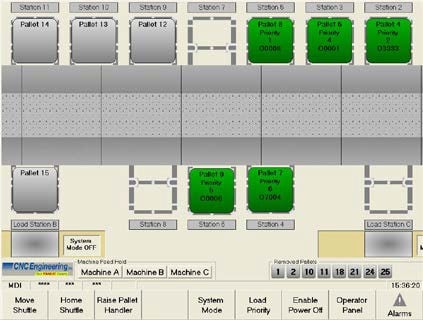

CNC Engineering, the leading FANUC Control Retrofitter in North America, has substantially updated its Open Vision™ Cell Control Retrofit Solutio n. Open Vision™ Cell Control retrofit packages include an improved operator interface with the ability to control multiple machines and pallets, running on a new touch screen industrial PC connected via Fanuc HSSB. A new Fanuc Powermate i-D control with a new Fanuc servo system replaces the existing pallet shuttle hardware. The new system offers easier operation and less downtime; plus better access to training, service, support and parts.

n. Open Vision™ Cell Control retrofit packages include an improved operator interface with the ability to control multiple machines and pallets, running on a new touch screen industrial PC connected via Fanuc HSSB. A new Fanuc Powermate i-D control with a new Fanuc servo system replaces the existing pallet shuttle hardware. The new system offers easier operation and less downtime; plus better access to training, service, support and parts.

The Open Vision™ Cell Control software package was originally designed to meet the needs of Makino MMC operators. While the new software emulates existing MMC functionality in an easy-to-use, touch screen application it is not limited to Makino and can be customized for other makes of manufacturing cells.

Open Vision™ Cell Control software features include:

User-friendly HMI: The graphical user interface of Open Vision™ Cell Control Software allows the operator to easily set and view the status of the pallets and pallet stations. Pallets can easily be marked as “Ready to Load” and their load priority can be easily set or changed to alter the order in which pallets are processed.

Improved Pallet Placement: Makino’s MMC system required a pallet to be moved to the workstation before it could be marked as “Ready to Load” and made available to the machine. This is no longer necessary, as any pallet can be moved directly to the machine from any pallet station.

as any pallet can be moved directly to the machine from any pallet station.

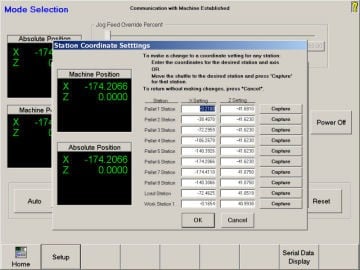

Flexible Workstation Settings: The original MMC configuration designated two pallet stations as workstations, thereby limiting the number of potential pallet stations. The functionality of these two stations can now be determined by the operator and set with a simple click of the mouse (or touch of the screen). These stations can be designated, independently, as either a pallet station or a workstation.

Home/Random Pallet Placement: The new “Random” configuration setting allows the operator to specify whether a pallet can be moved to any available pallet station, rather than having to be moved to its specific, “Home” station. The “Random” configuration can result in faster Cell Control operation and increased spindle utilization.

Direct Machine-to-Worksation Pallet Placement: Another new configuration setting allows the operator to specify that pallets should be moved directly to any available workstation upon being removed from the machine. This allows the operator to more easily access the processed pallet and perform any post-machining operations.

Manual Machine Functions: The system’s Operator Panel allows the operator to move the shuttle in MPG and Jog modes. It also allows the operator to raise and lower the pallet on the shuttle. These functions provide a way of manually moving pallets from station-to-station, including the load station, without being in Auto mode. They also aid in the setup of the machine.

Improved Setup Procedure: Using the manual mode of the Operator Panel, the system’s setup screen allows for capturing the shuttle’s position at the press of a button. This means quick and easy establishment of the shuttle position at each of the pallet stations, should a change be necessary due to mechanical changes or repositioning of the stations.

Diagnostics/Troubleshooting: Access to the Fanuc control ladder, settings and other diagnostic tools is provided through the use of Fanuc HSSB-based software, including the Ladder Editing Package and CNC Screen Display. This access will help in any problem resolution or changes that may be required in the future.

Popular Content

Even More Standard Options for FANUC 0i-F Plus Controls

The capabilities of today's FANUC control systems can provide powerful options to older machines that can improve your...

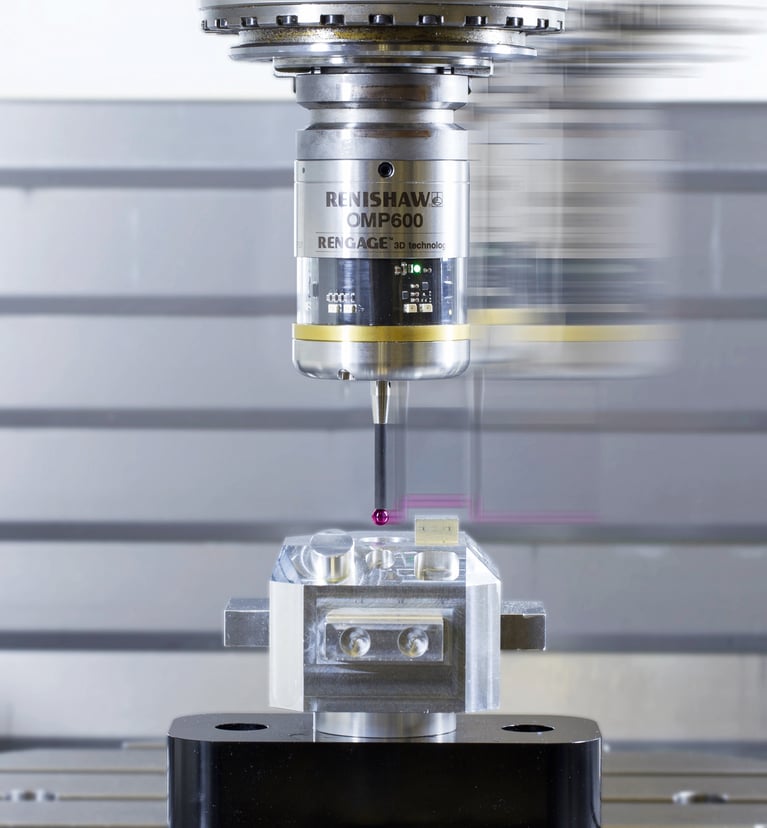

Decreased Cycle Time with Renishaw Inspection Plus Update

The capabilities of today's FANUC control systems can provide powerful options to older machines that can improve your...